Consisting of thinned hydrated lime, whitewash (or more properly, limewash) was used as a substitute for more expensive paints to brighten utilitarian spaces. Coating the walls of cellars, kitchens, dairies, and garrets, whitewash gave a room a tidy, hygienic appearance, and was cheap and easy to apply.

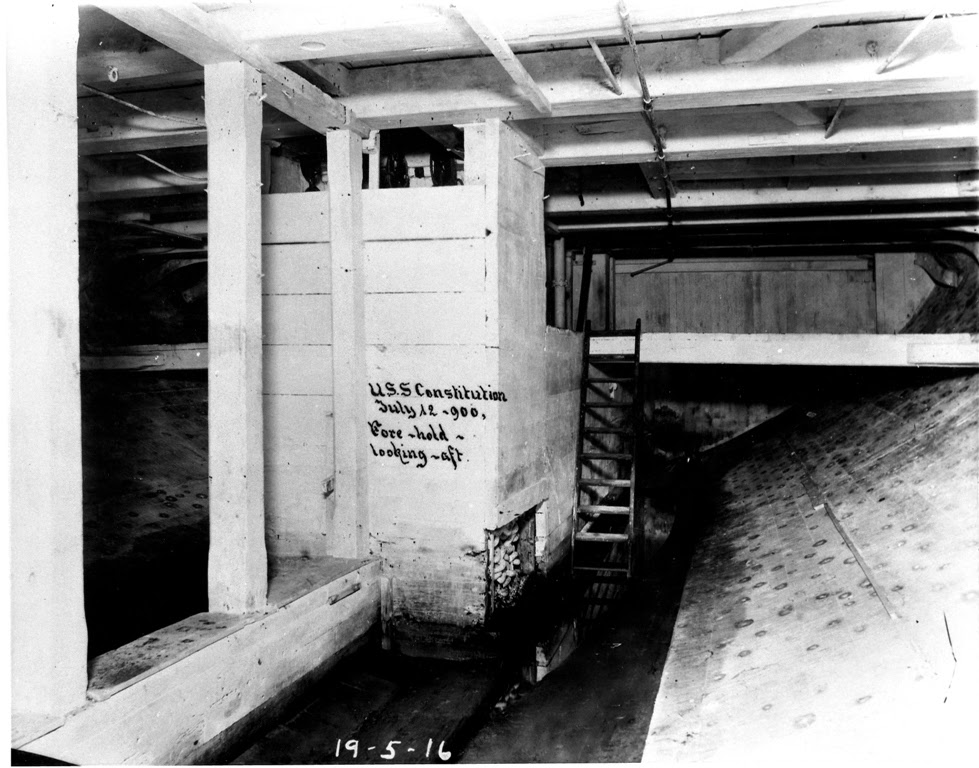

The penurious early US Navy loved whitewash too. The exteriors of the ships were protected and enlivened with several coats of glossy oil-based lead paint, but the spaces deeper in the hull were invariably coated in whitewash. As early as July 1799, Constitution’s log records the crew whitewashing between decks. They brushed it on the cable tier, the hold, the forward storerooms, the berthdeck, and the bulkheads on the gundeck. They reapplied the concoction every few months. In October 1812, the crew whitewashed the cockpit, probably to remove the grisly evidence of battle triage and surgery that had taken place there two months earlier. In 1826, Chaplain George Jones reported that “The beams above [the berthdeck], are white-washed; and I have frequently seen the captain rub his white glove against, them, and then examine, to see whether it had been soiled or not: parts of the deck are white-washed every morning.”

Part of the reason the Navy so loved whitewash was the perception that it created a healthful living and working environment. While early naval surgeons probably didn’t know why exactly, they were certainly correct about the healthful benefits of the stuff. Whitewash was made by slaking (or soaking) quicklime (CaO) in water. The slaked lime was highly alkaline, with a pH of about 12.4. Applying this to wood was sufficient to kill most bacteria on the surface. As whitewash cured, it absorbed carbon dioxide from the atmosphere and turned into calcium carbonate (CaCO3). Calcium carbonate is still slightly alkaline, with a pH of about 9.4. Either way, those concerned with the health of sailors favored whitewash for its antiseptic properties.

Whitewash is also non-flammable. Period paints, besides containing lead oxide pigments, used turpentine as a solvent. Scores of ships caught fire over the years because sparks fell on wet paint (perhaps the most spectacular example was burning of L’Orient, the French flagship at the 1798 Battle of the Nile. Supposedly, the ship had been newly painted the day before the battle, and fire from the guns’ muzzles or a burning wad set the ship ablaze).

Despite these benefits, whitewash fell out of favor for shipboard use by the middle of the 19th century. As early as 1826, Constitution’s interiors began to receive coatings of paint. One reason for this may be the inflexibility of whitewash. Unlike a paint film, which can flex, whitewash forms a hard coating. As a ship flexed at sea, it is likely the whitewash cracked and flaked off. It could be reapplied easily, but for a ship on active duty, it needed constant upkeep.

Whitewash could also become fodder for youthful shenanigans. One famous but unsubstantiated story, sometimes involving Commodore Charles Stewart, goes like this:

The captain “found great fault one morning, with the precincts of the galley. The midshipman of the deck was following, as is usual, and received a severe hazing for it; which was terminated with an order that every thing should receive a double coat of whitewash. ‘Every thing, sir?’ enquired the middy. ‘Yes sir, every thing.’ Judge the captain’s surprise, next morning, when a favorite milch-goat of his, stalked into the cabin, white-washed all over; with not a hair of her jet black coat to be seen. The midshipman was arrested, as he deserved to be, but was soon after restored again.”

The Author(s)

Matthew Brenckle

Research Historian, USS Constitution Museum

Matthew Brenckle was the Research Historian at the USS Constitution Museum from 2006 to 2016.