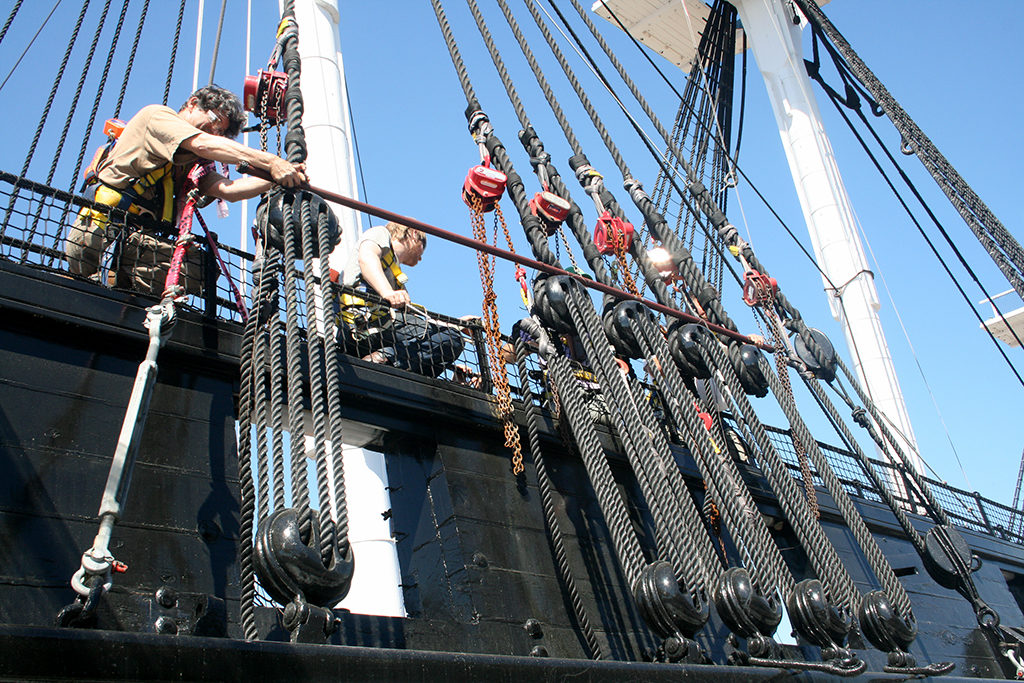

The warm summer days in the Charlestown Navy Yard are a boon for USS Constitution‘s current restoration in Dry Dock 1. The Naval History & Heritage Command Detachment Boston ship restorers and riggers are moving along on several projects. Some work, such as the re-rigging of the mizzen mast, is highly visible to the visiting public. Other work, such as caulking the hull below the waterline, is out of sight, far down in the dry dock.

Aloft – with USS Constitution‘s riggers

USS Constitution was down-rigged to just her three lower masts before she entered Dry Dock 1 on May 18, 2015. The removal of the upper masts and rigging lightened the ship so that she would safely cross the dry dock’s sill with more than enough water under her keel. Since last winter the NHHC Detachment Boston riggers have been overhauling the rigging that was removed and manufacturing new rigging where needed.

Beginning with the mizzen mast (the aftermost mast on the ship), the fighting top was refurbished and installed. New mouses are being made for the stays and new ratlines are being installed on the lower shrouds.

A-low – caulking in the depths of the dry dock

USS Constitution‘s copper sheathing on her lower hull, which was installed in 1995, was removed beginning in the summer of 2015. NHHC Detachment Boston was prepared to renew up to 30 below-the-waterline hull planks, but only needed to replace a few planks either whole or in part at the waterline. The preservation of the planks is due to the rot-resistant nature of the white oak exterior planking, the felt and copper protecting the planks from ship worms, and the preservative nature of Boston Harbor’s salt water. As a result, renewing the caulking below the waterline began much sooner than anticipated. Detachment Boston ship restorers are now busy reefing the hull seams using a curved iron “hook” to pick out the old oakum and preparing the seams for new cotton batting (if necessary) and several strands or “threads” of oakum.

“To Calk, or Caulk, to drive a quantity of oakum…into the seams of the planks, in the ship’s decks or sides, in order to prevent the entrance of water. After the oakum is driven very hard into the seams it [the caulked seam] is covered with hot melted pitch…to keep it from rotting.” [Courtesy Falconer’s New Universal Dictionary of the Marine, 1815]

USS Constitution has two miles of plank seams, port and starboard, for a total of four miles of seams below the waterline. By the time the NHHC Detachment Boston ship restorers finish the caulking, approximately 10 miles of oakum will have been used to make “Old Ironsides'” lower hull watertight.

USS Constitution‘s lower hull was first coppered in the spring of 1797, a few months before she was launched from Edmund Hartt’s shipyard in Boston’s North End. The original copper was manufactured in Great Britain. By 1803, when she was re-coppered before her departure for the Mediterranean Sea as flagship of Commodore Edward Preble’s squadron, Paul Revere’s new rolling mill in Canton, Massachusetts supplied the second set of copper sheets.

Rigging work on “Old Ironsides” will continue throughout the restoration and even after she is relaunched from Dry Dock 1 in the summer of 2017. Work below the waterline will culminate with the installation of thousands of new copper sheets, beginning as early as September 2016. The coppering will last several months. Visitors are welcome to stop by the USS Constitution Museum and sign their names onto a sheet of copper that will be installed on the ship.

_____

The activity that is the subject of this blog article has been financed in part with Federal funds from the National Maritime Heritage Grant program, administered by the National Park Service, U.S. Department of the Interior, through the Massachusetts Historical Commission, Secretary of the Commonwealth William Francis Galvin, Chairman. However, the contents and opinions do not necessarily reflect the views or policies of the Department of the Interior, or the Massachusetts Historical Commission, nor does the mention of trade names or commercial products constitute endorsement or recommendation by the Department of the Interior, or the Massachusetts Historical Commission.

The Author(s)

Margherita Desy, Historian, Naval History and Heritage Command Detachment Boston

Historian, Naval History and Heritage Command

Margherita M. Desy is the Historian for USS Constitution at Naval History and Heritage Command Detachment Boston.

Kate Monea

Manager of Curatorial Affairs, USS Constitution Museum

Kate Monea is the Manager of Curatorial Affairs at the USS Constitution Museum.

Phaedra Scott

Content Developer, USS Constitution Museum

Phaedra Scott was the Content Developer at the USS Constitution Museum from 2016 to 2017.